Reflecting objectives

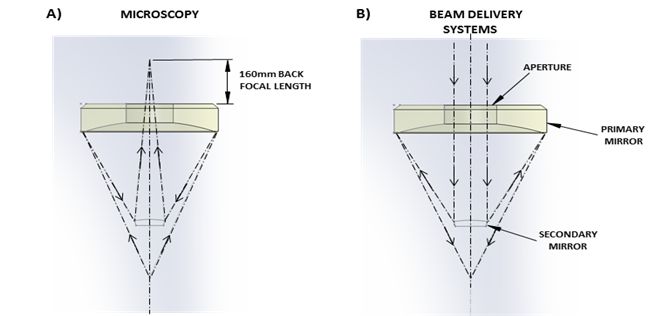

The original Beck/Ealing reflecting objectives were originally developed for microscopy and are only offered by a few manufacturers worldwide. They are based on a two-mirror system and, unlike refractive objectives, are free of chromatic aberration. The reflecting objectives are a combination of mirror and lens and consist of primary and secondary mirrors for light focusing and image formation. Originally developed for microscopy, the reflective lenses are now commonly used in beam delivery systems. They have unique optical properties and advantages compared to standard lenses:

- Free of chromatic aberration

- Longer working distance in relation to magnification

- Larger numerical apertures for higher light gathering performance

- High transmission power from the UV to far into the IR (various coatings available)

- Low peak to valley wavefront error ≤ λ/4 (0.25 λ), λ/14 RMS @633nm

Technical data of the standard models:

| Property | Beck Optronic Solutions Model No | |||||

|---|---|---|---|---|---|---|

| 5001-000 | 5002-000 | 5003-000 | 5004-000 | 5006-000 | 5007-000 | |

| Magnification | x15 | x15 | x25 | x36 | x52 | x74 |

| Numerical Aperture | 0.28 | 0.50 | 0.40 | 0.50 | 0.65 | 0.65 |

| Focal length (mm) | 13.35 | 13.41 | 8.00 | 5.41 | 3.55 | 2.54 |

| Visual FOV (mm) | 1.20 | 1.20 | 0.72 | 0.50 | 0.34 | 0.24 |

| Obscuration | 25.0 % | 21.5 % | 22.5 % | 13.0 % | 17.5 % | 15.0 % |

| Transmitted wavefront error | ≤ λ/4 P-V, λ/14 RMS @663nm | ≤ λ/4 P-V, λ/14 RMS @663nm | ≤ λ/4 P-V, λ/14 RMS @663nm | ≤ λ/4 P-V, λ/14 RMS @663nm | ≤ λ/4 P-V, λ/14 RMS @663nm | ≤ λ/4 P-V, λ/14 RMS @663nm |

| Working distance (mm) | 24.5 | 23.2 | 14.5 | 8.6 | 1.9 | 1.0 |

| Small mirror diameter (mm) | 7.30 | 13.40 | 6.30 | 5.60 | 4.60 | 3.35 |

| User adjustmendt for tubelength & cover glass thickness | Fixed (factory set) | Fixed (factory set) | Fixed (factory set) | Yes | Yes | Yes |

| Range of cover glass thickness | 0 - 3.0mm* | 0 - 3.0mm* | 0 - 3.0mm* | 0 - 1.0mm | 0 - 1.0mm | 0 - 1.0mm |

| Range of Tube-length (mm) | 80 - ∞* | 80 - ∞* | 80 - ∞* | 90 - ∞ | 120 - ∞ | 120 - ∞ |

Customer-specific adaptations of a mechanical nature or e.g. vacuum suitability are possible, in some cases only with low extra costs.

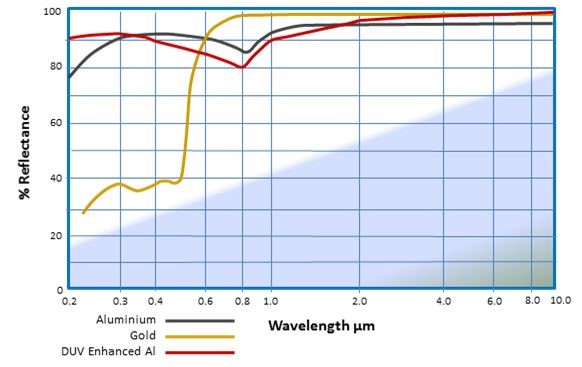

As standard, the reflecting objectives are supplied with aluminium-coated mirrors. This ensures the widest spectral coverage from UV to IR. The objective is limited with regard to the usable performance. For applications requiring high power, the manufacturer offers alternative coatings, see table. Special coatings can also be offered for very special applications.

| Range | Reflectance | Coating | Suffix |

|---|---|---|---|

| 250nm - 10µm | 89.0% average | Aluminium | -000 |

| 190nm - 10µm | >89.0% | DUV Enhanced Aluminium | -190 |

| 700nm - 15µm | 98.0% | Gold | -120 |

The standard objectives have a 3 legged spider (to support the secondary mirror) which minimises diffraction but produces a six point flare pattern.

A “4 legged spider” produces a larger diffraction but at the same time produces a light reflex pattern with only 4 dots, which is sometimes preferred by users. Without specification the standard is always delivered with “3 legged spider”.

Notes:

If back reflections may be an issue in your application a matt black dimple can be ground into the secondary (smaller) mirror. If you require a clearance hole through the secondary mirror please contact us to discuss the options available.