Positioning with stepper motors

Unlike piezo-driven axes, stepper motors are suitable for positioning heavier objects. The design of the motors is very robust and enables small positioning movements of the table despite high thrust and tensile forces. Since it is an external drive, the Micronix step-driven axes are not quite as space-saving as the piezo-driven ones.

Overview stepper motors

| Name | Type | Travel in mm | Load in kg | Encoder | Environment |

|---|---|---|---|---|---|

| VT-21S | Linear | 10 | 1 | Analog, Digital | HV |

| VT-21L | Linear | 26 | 1 | Analog, Digital | HV |

| PPS-20SM | Linear | 12, 18, 26, 51 | 2 | Analog, Digital | HV |

| PPS-28SM | Linear | 26, 51, 76, 102 | 5 | Analog, Digital | HV |

| PPS-60SM | Linear | 25, 50, 100, 200, 300 | 15 | Analog, Digital, Digital (low cost) | HV, UHV |

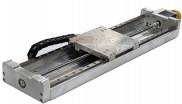

| PPS-110 | Linear | 100, 200, 300, 500, 1000 | 25 | Digital | HV, UHV |

| VT-50L | Linear | 50, 100, 200, 300 | 20 | Analog, Digital | HV |

| PR-50SM | Rotation | 360° | 2 | Analog, Digital | HV |

| PG-50SM | Goniometer | +-5° | 2 | Analog, Digital | HV |

| ES-50SM | Stroke | 10 | 1 | Analog, Digital | HV |

| PZS-90 | Stroke | 35 | 15 | Analog, Digital, Digital (low cost) | |

| MP-21 | Pusher | 12, 25 | 2 | - | HV |

| MPA-20 | Pusher | 12 | 10 | - | UHV |

Control:

The MMC-200 is a cost-effective stepper motor controller. It enables speeds above 5 mm/s with closed loops of 50 nm. Multiple units can be stacked as a compact multi-axis module and connected to a computer via a single USB or RS-485 cable. The MICRONIX Motion Control Language allows easy programming with simple ASCII commands.